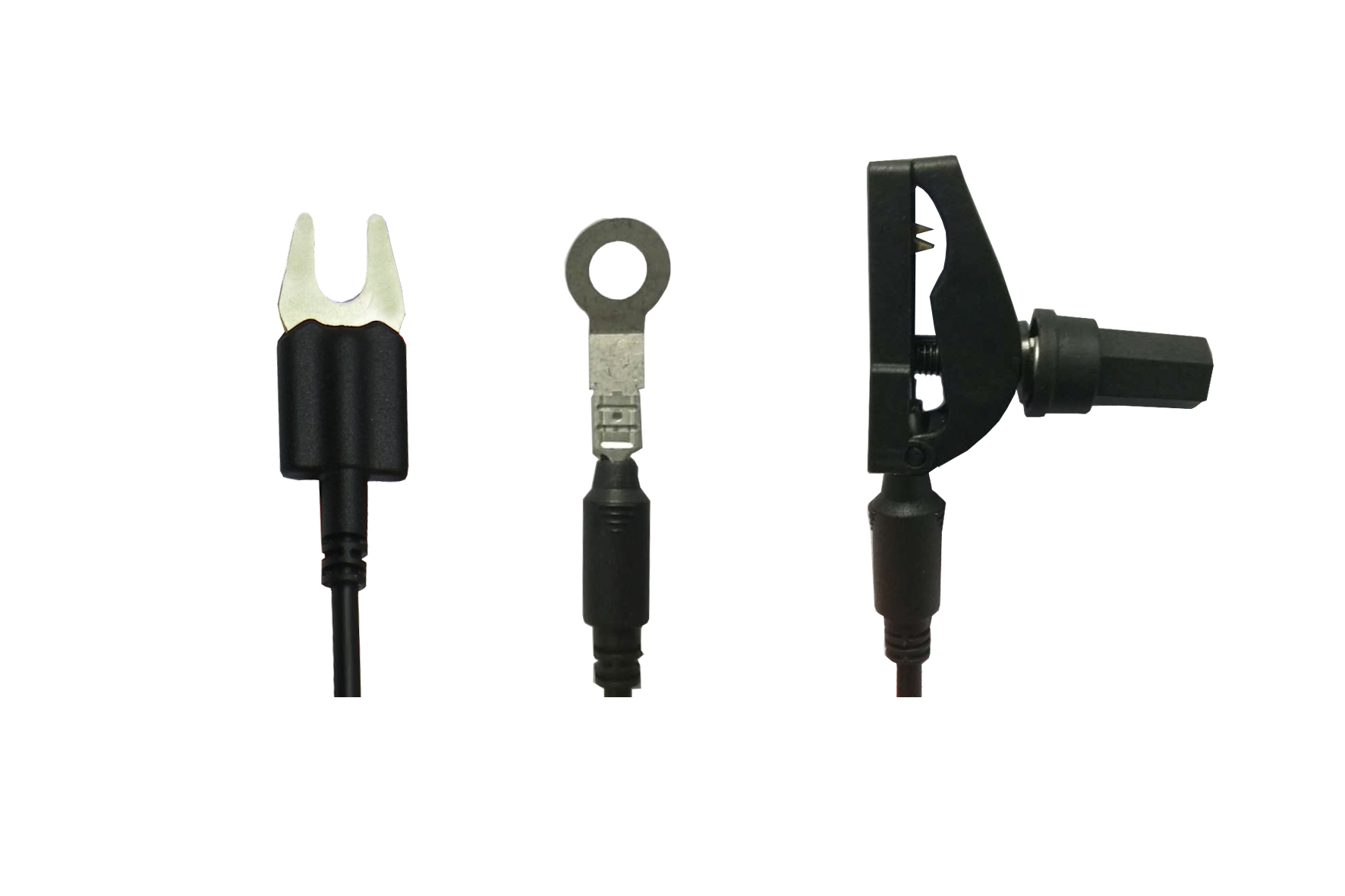

1.Very simple wire connection, easy-going installation and commission onsite

* PITE 3923 adopts the technology of Power Line Carrier (PLC) for data transmission.It takes advantage of communication circuit with battery string itself. No need to

connect extra wires or cables for data transmission.

* We use cloud computing platform for data management. Users do not need to purchase server or install server software by themselves. Just one login account and

password from PITE will enable user to view everything about their battery condition simply in a smart phone.

2.PITE’s advanced mathematical model, consistent and precise measurement

* PITE has patented technology of multi-frequency measurement based on our years experience for battery management. And we have built very mature mathematical

model that will precisely predict battery capacity (SOH).

* Sectionalized connection enables one IMM (Intelligent Monitoring Module) to connect with multiple cells with accurate measurement and quick diagnosis for battery

malfunction.

3.Cloud server + mobile communication

* All you need is a smart phone to view battery status and tendency.

* Timely SMS warning info keeps you alert for lag-out or weak batteries.

4.Smart and convenient methods for battery management

* Complete monitoring for voltage, internal resistance, temperature and periodical monitoring for charge/discharge current. It helps you find out lag-out batteries

beforehand.

* In case of power grid outage or manual switch-off of power grid for maintenance,system will automatically switch to discharge monitor. And it will record discharged Ah

and voltage/temperature changes during discharge. This will further help judge the lag-out batteries.

* In case of battery malfunction, system will automatically send warning message to technician for immediate action.

* Map orientation of battery sites will help technicians reach site conveniently.

5.With very good price for different industries

* Unique technology for battery sectionalized measurement is different from traditional measurement for EACH cell. Each battery string can be sectionalized as several bigger sections. And each IMM is connected with one section containing several cells. * This application will greatly reduce the amount of IMMs that are connected with batteries. This will make PITE 3923 very economical to use in different industries.

6.Unique technology for system resting

* Each IMM get very low power from batteries, no harmful to batteries that aremonitored.